Coupled Analysis

Coupled analysis refers to an analysis that takes into account the effects of two or more physical phenomena on each other. For example, when a high-temperature, high-velocity fluid impinges on a structure, it can have a significant effect on heat propagation and deformation, and the resulting fluid forces can have an even greater effect on the deformation of the structure. Coupled analysis is necessary to correctly evaluate these mutually influential events. In general, there are two types of coupled analysis: two-way coupled and one-way coupled. In unidirectional coupled analysis, data is exchanged at each analysis time step. In addition, it is not uncommon these days to consider factors that arise in the manufacturing process at the design stage. In this regard, the following are some of the most common use cases of coupled analysis that we have heard about recently.

Scenes requiring coupled analysis (examples)

Product Design

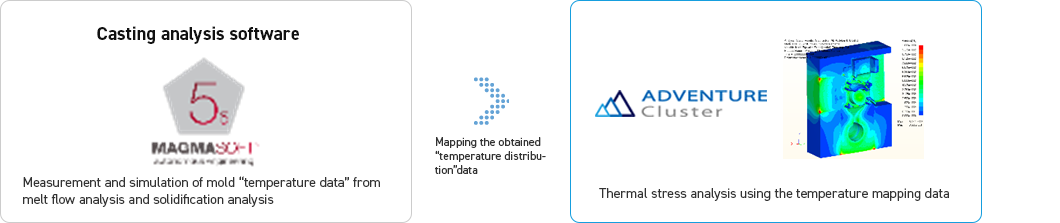

- Castings

- Warping/burn that affects the function of the product.

- Forged products

- After heat treatment, the strength of each part of the product is different, and some parts are damaged.

- Resin products

- Warpage/shrinkage/whitening that affects the function of the product.

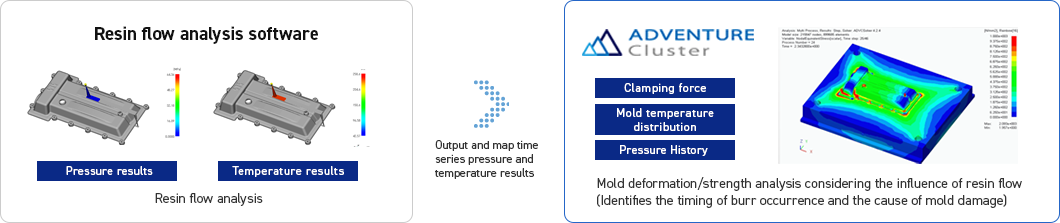

Mold Design

- Die casting molds

- Cracks affecting product function. Burr / slide galling / push pin damage during release / die fatigue life due to heat strength variation due to differences in residual stress / breakage occurs

- Injection molds

- Burr / slide galling / unbalance of heat shrinkage / warpage generation.

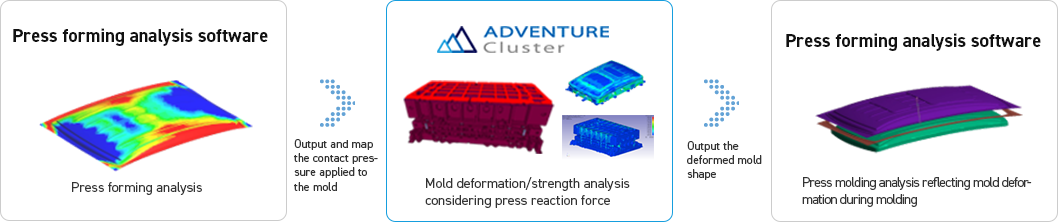

- Press dies

- Product dimensional deviation due to press mold breakage / mold damage during molding / prediction of springback and mold projection.

Coupled analysis with other software enables more accurate evaluation and study.