Application examples in casting products and molds

Mold release analysis of casting products

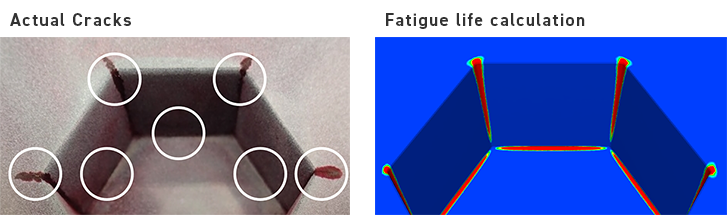

Mold fatigue life analysis

Honda Motor Co., Ltd. uses ADVENTURECluster as a tool for solving problems in product development. In the field of production engineering, there is a growing need to reproduce phenomena occurring on actual machines by CAE to achieve both mass production and functionality. ADVENTURECluster, which excels in large-scale nonlinear structural analysis, is effectively used to improve the calculation accuracy of analysis items with strong nonlinearity such as mold opening/mold release resistance, casting deformation, finished casting dimensions, and the life of mold structural components.

Analysis overview

| Target | Die casting and products |

|---|---|

| Items | Transient heat transfer analysis, thermal stress analysis, low-cycle fatigue analysis |

| No. of nodes | 5 million nodes |

|---|---|

| Computation time | 120 hours |

Topics 1

Background・Issues

For fatigue prediction of die casting molds, it is important to consider mold temperature changes during the production process. Till now, the mold temperature results obtained from casting analysis are always mapped onto model for structural analysis .

However, there were some restrictions and complicated work required for use, such as the lack of support for large-scale casting analysis, the work-hours required for mapping, and the upper limit of available processes, which could be an obstacle.

Application Technology

ADVENTURECluster’s non-steady heat transfer analysis can calculate the ever-changing temperature state of a large-scale model at high speed, and ADVENTURECluster also needs mold temperature results to operate thermal stress analysis. So that we got an idea that ADVENTURECluster can use its own temperature data to operate thermal stress analysis and no longer necessary to map mold temperature results from other casting analysis. Which is expected to reduce work-hours . Therefore, the client verified this idea.

During the verification, we received a request to develop a latent heat function, which was not implemented at that time. Then the developer implemented the new function and the client used it to perform the analysis. Finally, it was confirmed that the temperature distribution results with the required accuracy can be obtained. And the client adopted this function and method.

Effect

Low-cycle fatigue analysis of die-casting mold models enables prior prediction of crack initiation points, reducing the number of prototypes and mold modifications. And the development flow that does not require large-scale casting analysis had been established, then at the same time, the work-hours required for model construction had been successfully reduced.

Topics 2

Issues

Die-cast products solidify in the mold and are held by the mold due to thermal contraction, etc. When they are removed, they are pulled out of the mold by ejector pins placed in the mold. The placement of the ejector pins is conducted during mold design process, but if they are not placed properly, the ejector pins may break or the products may deform, which will result in high costs and work-hours required to modify the mold.

Simulation is an effective way to study proper pin placement, but it is necessary to accurately reproduce the behavior of a high-temperature product holding onto the mold.

Application Technology

The coefficient of linear expansion, which used to be a theoretical value, was reviewed and changed to a value closer to reality, and the material model RDNLK (Rate- Dependent Non-Linear Kinematic Hardening) was adopted to represent material properties such as creep and stress relaxation that are prominent in metals at high temperature.

Effect

The prediction accuracy of the products holding force onto the mold was improved, and the actual measurement and CAE results were confirmed to be in agreement during the holding force test using test pieces. By applying this technology to model development, The client was able to improve the ejector pin placement and the accuracy of product shape dimensions, thereby development work-hours was also reduced.