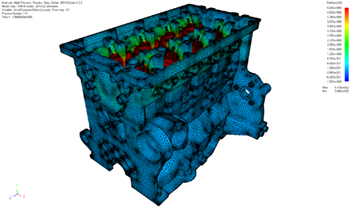

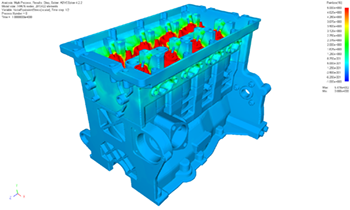

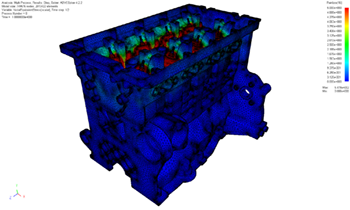

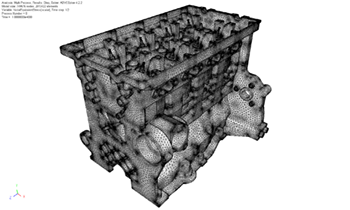

Engine Strength Analysis

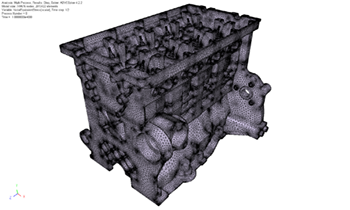

In this analysis, we carried out a series of operations, including press fitting of the engine block, bolt fastening, and explosion. Although the model is large and has many parts, it can be analyzed without simplifying the model, which leads to a reduction in the amount of preprocessing work, and it is widely used in this field. Because the engine model is made by large-scale solid element, that ADVENTURECluster's good at, so that calculation speed is fast. In addition, ADVENTURECluster has good parallel efficiency, and even if many cores are installed, parallel efficiency does not reach a ceiling, and parallel calculation is possible.

Analysis overview

| Target | Engine block |

|---|---|

| Items | Static analysis, nonlinear contact analysis, nonlinear heat transfer analysis |

| No. of nodes/parts | 9,940,331 nodes / 39 parts |

|---|

Background/Issues

There are many parts and the contact calculation may not converge.

The calculation load is high due to the 6 million elements.

(Calculation process) Press-fitting, bolt fastening, explosion

Analytical Needs

We want to analyze the stress evaluation area in more detail.

Calculations can be made with related parts attached (supercharger, exhaust manifold, transmission)

Advantages

Large-scale model high-speed calculation is possible

Good parallel efficiency

CAD model shape not simplified

| Process | No. of steps | No. of parallel processes and calculation time(Hour) | ||||

|---|---|---|---|---|---|---|

| 8Core (1Node) |

16Core (1Node) |

32Core (2Node) |

64Core (4Node) |

128Core (8Node) |

||

| Press fitting | 4 Steps | 1.6 | 1.0 | 0.7 | 0.5 | 0.4 |

| Bolt fastening | 4 Steps | 5.8 | 3.6 | 2.2 | 1.4 | 0.9 |

| Explosion | 4 Steps | 4.5 | 2.5 | 1.6 | 1.1 | 0.7 |

| Total | 12 Steps | 12.0 | 7.1 | 4.5 | 3.0 | 2.0 |