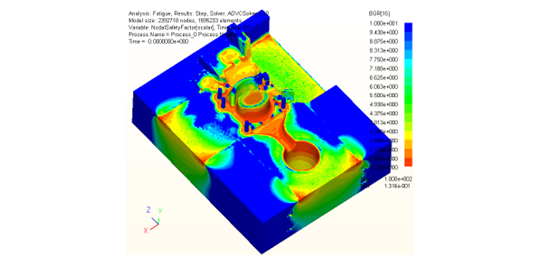

Thermal fatigue analysis of molds

In this analysis, we carried out a strength analysis of the casting mold. The temperature distribution obtained from the casting analysis software can be used as the boundary condition for thermal stress analysis. This makes it possible to evaluate the strength of the mold, taking into account the load applied to it during the casting process. High-cycle fatigue analysis is performed based on the stress obtained. The stress amplitude, mean stress, and safety factor are calculated. ADVENTURECluster excels at large-scale solid element models, resulting in fast calculation times.

Analysis overview

| Target | Mold |

|---|---|

| Items | Fatigue analysis, heat transfer analysis, static analysis |

| No. of nodes/parts | 1,585,847 nodes / 7 parts |

|---|

Background/Issues

The scale of the mold assembly model is large, so it takes a long time to calculate.

Analytical Needs

We want to analyze the strength of the mold, taking into account the load that occurs during the casting process.

We want to use the amount of mold opening to predict burrs.

We want to identify the cause of the damage caused by high temperatures.

Advantages

Using the ADVENTURECluster standard mapping tool "collabo", it is possible to easily map the temperature data of casting analysis software.

Large-scale models can be calculated quickly.